Electrolytic iron Fe lump, Iron supplier

Grade:

4N

Standard:

GB/T 3211-2008

Surface treatment:

Color:

Metallic color

Electrolytic iron is much purer than iron made by other existing methods, with an iron content of 99.95%, and its properties are quite different from ordinary iron. It is extremely soft and malleable. Compared with general commercial iron, it has much better corrosion resistance to alkali solutions and molten alkalis, but it is easily soluble in acid. It has extremely good magnetic permeability, using it to make transformers and motors can greatly reduce the hysteresis loss. Its conductivity is also good. In some cases, electrolytic iron can be used as a good substitute for copper. The electrolysis method can directly deposit sheets, ribbons and tubes, which can be used to manufacture chemical equipment. In areas lacking large-scale machinery and equipment for the manufacture of seamless steel pipes, seamless iron pipes can be manufactured as long as there is electricity.

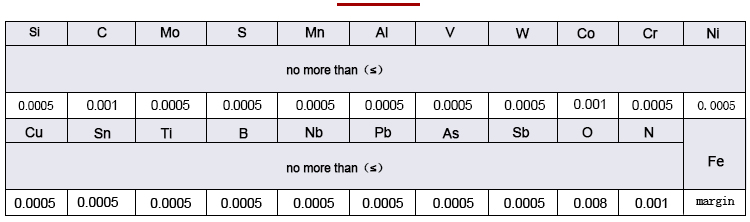

Electrolytic iron composition analysis

Electrolytic iron application

• Used in super heat-resistant steel, aircraft parts or nuclear energy-related machinery to high-tensile steel, etc.;

• Rare earth magnetostrictive alloy;

• Super heat-resistant alloys for aviation, aerospace and atomic energy industries, melts of newly developed alloys, electronic parts and components, magnets containing rare earth elements, standard materials for analysis, etc.;

• Electrolytic iron powder is used in catalysts, iron powder resins, reducing agents, high-purity reagents, etc. Soft magnetic parts, electronic components, high-performance and high-density parts;

• High-purity electrolytic iron can also be used to make colored alloy jewelry in precious metals. For example, adding different content of iron to gold can obtain blue, gray or black colored alloy jewelry.

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]